In the world of high-quality knives, swords, and other edged tools, few materials stand out as much as raindrop damascus steel. This captivating and distinctive pattern has become a symbol of fine craftsmanship and exceptional strength, beloved by artisans, collectors, and enthusiasts alike. The raindrop damascus pattern, with its swirling, droplet-like designs, is not only visually stunning but also demonstrates a long history of metallurgy and the pursuit of perfection in blade-making.

This article will explore the origins, creation process, and significance of raindrop damascus steel. We will also delve into why it has gained such popularity in modern times and what makes it a preferred choice for knife makers and collectors worldwide.

What is Raindrop Damascus?

Raindrop damascus refers to a specific pattern found in damascus steel, which is famous for its unique, multi-layered appearance. Unlike standard steel, which is made from a single piece of metal, damascus steel is created by folding and welding layers of different metals, usually steel and iron, to form a material that has remarkable strength, flexibility, and durability.

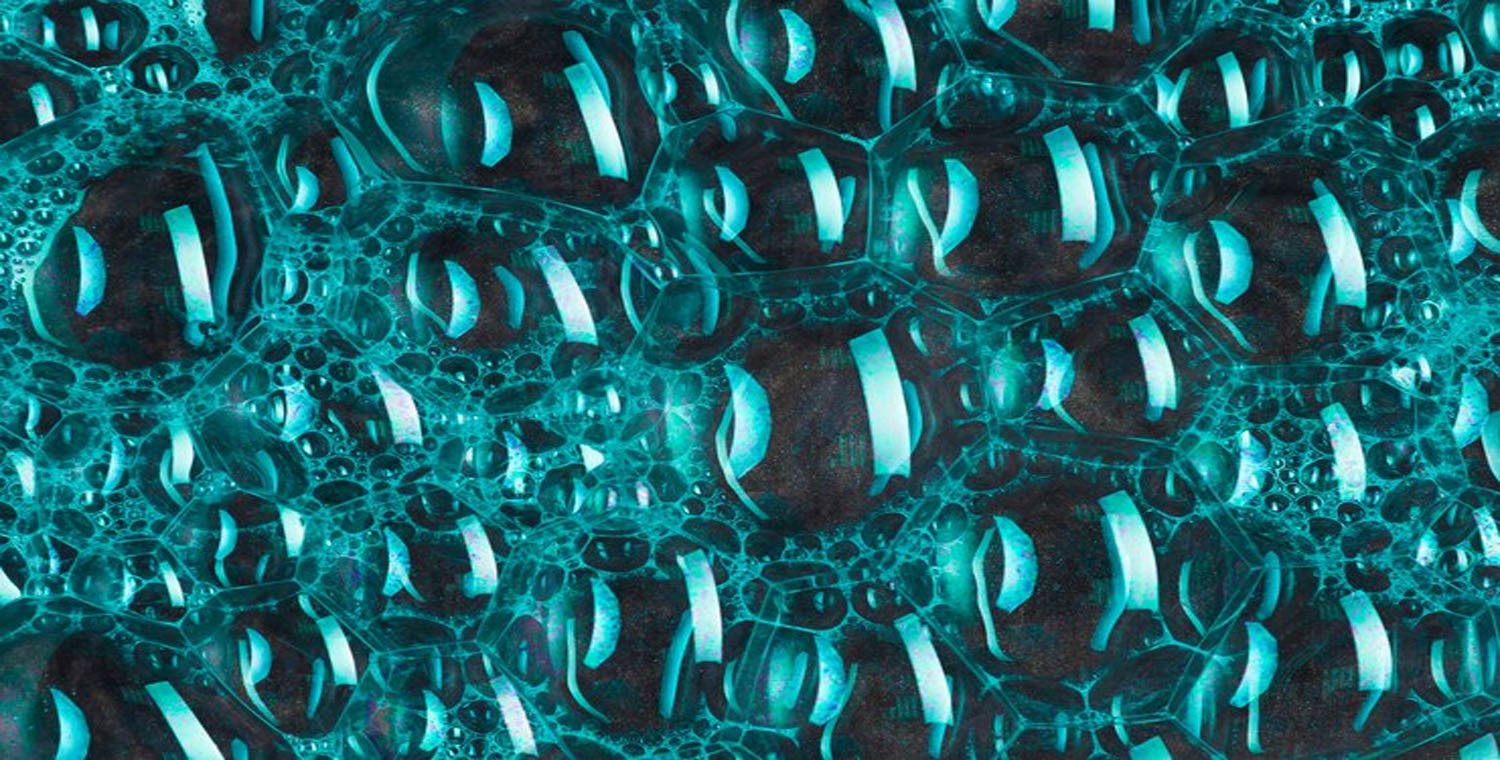

The raindrop damascus pattern is one of the many possible patterns that emerge when forging damascus steel. The design itself looks like a series of circular or oval droplets—resembling raindrops—interspersed with fine lines, which gives it a visually stunning, organic texture. This effect is achieved by manipulating the metal during the forging process, creating variations in the way the layers of metal fold and react to pressure and heat.

The visual appeal of raindrop damascus is not merely decorative—it also tells the story of the craftsmanship and meticulous process behind its creation. Each pattern is unique, and no two pieces will ever look exactly the same, making it highly prized by collectors and those who appreciate finely made, bespoke tools and weapons.

The History of Damascus Steel

The art of creating damascus steel has a long and fascinating history. It dates back more than a thousand years to the ancient Middle East, where it was used to create some of the finest weapons of the time. The name “damascus” comes from the ancient city of Damascus, which was renowned for its production of high-quality swords and knives.

Early damascus steel was made using a process known as wootz steel, which originated in India and was later adopted by the Middle Eastern craftsmen. Wootz steel was known for its high carbon content, which gave it extraordinary sharpness and strength. Blacksmiths and artisans in Damascus would combine this wootz steel with other metals to forge weapons that were not only functional but also visually striking. The unique patterns that formed in these blades were a byproduct of the welding process and a testament to the skill of the artisan.

However, the original methods for creating traditional damascus steel were lost over time, and the exact techniques used to produce it became a closely guarded secret. Modern damascus steel makers, including those working with raindrop damascus, use contemporary methods to recreate this iconic style, but the basic principles of folding, welding, and layering remain the same.

The Creation Process of Raindrop Damascus

Creating raindrop damascus is a highly skilled and labor-intensive process that requires expert knowledge of metallurgy and blacksmithing. Below is a breakdown of how this intricate steel pattern is crafted:

1. Selecting the Right Materials

The first step in making raindrop damascus is selecting the right materials. Typically, a combination of different steels or iron alloys is used, each contributing unique characteristics to the finished product. For instance, high-carbon steels are often combined with mild steel or low-carbon steel to create the right balance of hardness, flexibility, and strength.

Craftsmen may also choose to experiment with adding other metals, such as nickel, to create contrasting colors in the finished pattern. The choice of materials greatly affects the final look of the raindrop damascus blade.

2. Stacking and Layering the Steel

The next step involves stacking the selected pieces of steel into a billet, which is a block of metal that will later be forged into the blade. The layers of metal are carefully aligned to ensure an even distribution of different alloys, which will help create the characteristic pattern. The billet is then heated to a high temperature in a forge, softening the metal and preparing it for the next step.

3. Folding and Welding the Steel

Once the billet has been heated, it is hammered to flatten it into a thin sheet. This process is known as “forging.” After the sheet has been flattened, it is folded onto itself to create a new layer. The process of folding and welding the metal together is repeated multiple times to increase the number of layers. Each fold adds complexity to the blade and strengthens the bond between the different types of steel.

In raindrop damascus, the pattern is created during the folding process, where specific techniques are used to manipulate the layers and produce the characteristic droplet shapes. The craftsman may use tools to compress and twist the layers, creating the distinct swirling patterns that give raindrop damascus its name.

4. Patterning and Etching

Once the billet has been folded and welded, it is further manipulated to achieve the desired pattern. For raindrop damascus, the pattern is often created by pressing the layers together with specific tools, such as anvils or presses, to compress certain areas and create the circular or raindrop-like shapes.

Once the pattern is established, the blade is often acid-etched to highlight the contrast between the different layers of metal. The acid etching process enhances the visual appeal of the steel by darkening the areas with higher carbon content, allowing the lighter layers to stand out and create the unique pattern.

5. Shaping and Finishing

After the pattern has been formed, the blade is shaped into its final form. This includes grinding, polishing, and sharpening the edge. The blade is then heat-treated to ensure it has the right hardness and durability for its intended use. Finally, the blade is finished with a handle and any additional details, creating a functional work of art that is both visually striking and highly durable.

Why Choose Raindrop Damascus?

There are several reasons why raindrop damascus has gained such popularity in recent years. Here are just a few:

1. Aesthetics and Uniqueness

The most obvious reason people choose raindrop damascus is its striking visual appeal. The raindrop pattern is unlike anything else, with its fluid and organic design creating a stunning visual effect. Because each piece is handcrafted, every blade made with raindrop damascus is one of a kind. This uniqueness makes it highly desirable for collectors and enthusiasts.

2. Strength and Durability

Despite its beautiful appearance, raindrop damascus is incredibly strong and durable. The process of folding and welding the steel creates a dense, uniform structure that is resistant to wear and tear. The combination of different types of steel in the billet results in a blade that is both sharp and tough, with an ability to maintain its edge for longer periods.

3. Historical Significance

For those who appreciate the history and tradition behind damascus steel, raindrop damascus offers a modern take on an ancient craft. The centuries-old techniques used to create damascus steel have been passed down and perfected by artisans over time. By choosing raindrop damascus, you are participating in a long-standing tradition of metallurgy and craftsmanship.

4. Versatility

While raindrop damascus is often associated with high-end knives and swords, it is also used in a variety of other products, including axes, daggers, and even jewelry. Its versatility makes it a popular choice for both functional and decorative items.

Caring for Raindrop Damascus

To maintain the beauty and functionality of a raindrop damascus blade, proper care is essential. Regular cleaning and oiling of the blade will prevent rust and keep it looking its best. It’s also important to avoid using the blade on materials that could damage the edge, such as bones or hard metals. Storing the blade in a dry, safe place will help preserve its appearance and longevity.

Conclusion

Raindrop damascus is more than just a beautiful pattern—it is a testament to the skill, precision, and artistry of the blacksmith. The process of creating this unique steel is a delicate balance of science and art, producing blades that are both visually stunning and functionally superior. Whether you’re a collector, an enthusiast, or someone who appreciates fine craftsmanship, raindrop damascus offers a compelling combination of history, beauty, and durability that will undoubtedly continue to captivate people for generations to come.